Green lithium extraction technology solution

1、Background overview

2、With the rapid development of the global electric vehicle and energy storage industries, the demand for lithium carbonate as a key raw material continues to rise. However, current mainstream lithium extraction technologies (such as sulfuric acid roasting) suffer from complex processes, high investment costs, significant energy consumption, heavy pollution, and low resource utilization rates, making it difficult to meet the industry's trend towards efficient, green, and low-carbon development.

The new lithium extraction solution launched by AUPEX TECH PTY LTD is based on the advanced electromagnetic vibration separation concept, focusing on the core demands of modularization, high recovery rate, energy saving and environmental protection, and provides a complete set of systematic and engineering alternative processes for global lithium resource enterprises.

2. Highlights of the technical core

One-step lithium separation technology

Innovatively, the reaction induced by electromagnetic vibration is used to desorb lithium in gaseous form in ore, so as to realize the complete separation of lithium and vein stone in one step.

It effectively replaces the traditional "five-step process" (roasting, ball milling, leaching, solid-liquid separation and evaporation concentration), and greatly simplifies the production process.

The recovery rate is as high as 95%, and the residual lithium content of waste residue is only 0.3%, far exceeding the industry average level.

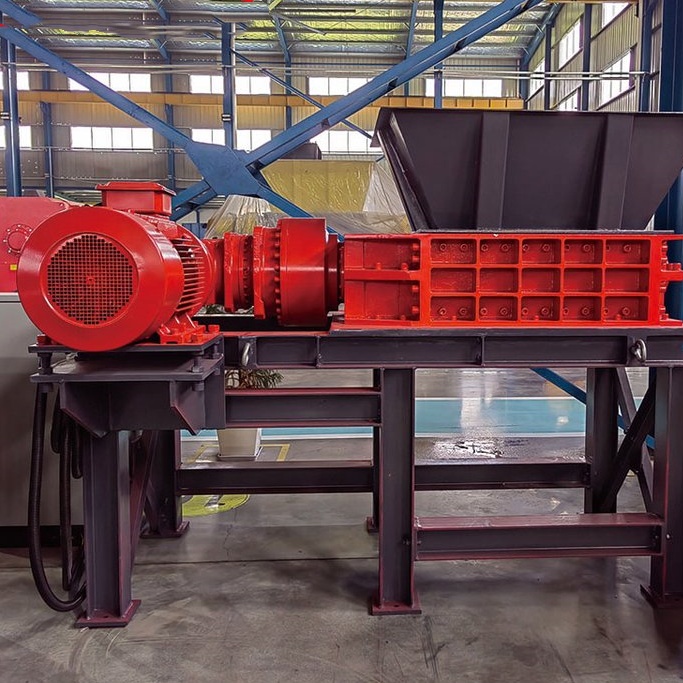

Modular process design

The lithium extraction system is designed according to four functional modules: raw material configuration, integrated separation, lithium enrichment and product preparation; each module can operate independently and be deployed quickly.

The mobile production unit is suitable for remote mining areas, pilot-scale verification or rapid capacity expansion projects.

Energy saving and environmental protection advantages

The overall energy consumption of the system is 50% less than that of the traditional sulfuric acid method, and the water resource consumption is only 30% of the original process.

The production process has no acid and alkali pollution, no hazardous waste residue, and the exhaust gas emission meets the environmental protection standards of many countries.

Waste residue can be reused as building materials.

Product adaptability and quality

Adapt to multiple types of lithium ore: spodumene, lithium mica, lithium clay, tailings, etc.

It can be used to prepare high purity lithium carbonate, lithium hydroxide and other products with a purity of more than 99.5%, which meets the battery grade application standard.

Third, the advantages compared with traditional technology

Compare projects Traditional sulfuric acid method AUPEX modular electromagnetic vibration process

Process steps 5~6 complex processes One step lithium separation, short process

capitalized cost 300 to 500 million yuan per ten thousand tons Reduce by more than 100 million yuan

floor space About 200 acres Reduce by 50%

energy consumption tall Reduce by about 50%

Water consumption A large amount of water is used for circulating evaporation Water saving is more than 70%

percent recovery 80~85% ≥95%

pollutant discharge There is a lot of waste water, waste gas and acid fog Clean emissions, waste can be reused

Construction period Long, complex equipment Modular rapid deployment

Iv. Applicable scenarios and cooperation modes

Start-up or expansion of lithium salt manufacturers: suitable for annual production scale of 10,000 tons or rapid replication production line.

Overseas remote mining area: mobile module test is carried out first to save the initial investment and verify the feasibility.

Investment consortium/mining rights party: provide engineering package, technology authorization, joint venture construction and other cooperation methods.

5、Feasibility schedule

It has been verified by a complete scale production process (monthly processing capacity of 600KG), and an annual production line of 80,000 tons is under construction.

V. Conclusion

AUPEX TECH PTY LTD The technology promoted is grounded in the global trend of green and low-carbon development, integrating advanced separation mechanisms with process engineering design. It can effectively address the bottlenecks of traditional processes. We sincerely hope to engage in deep cooperation with more lithium mining resource companies in Australia and around the world, jointly promoting the sustainable and high-quality development of the lithium industry chain.

Contact: AUPEX TECH PTY LTD

Email: aupexjixiang@gmail.com

Tel: +61-420702863