Waste Lead Acid Battery Crushing Breaking And Recovery Plant Description

The Waste Lead Acid Battery Crushing Breaking And Recovery Plant includes equipment like a lead acid battery crusher, a lead side-blowing furnace, lead refining gear, lead slag equipment, and other related machinery. We need a project design to put all these things together to produce refined lead metal.

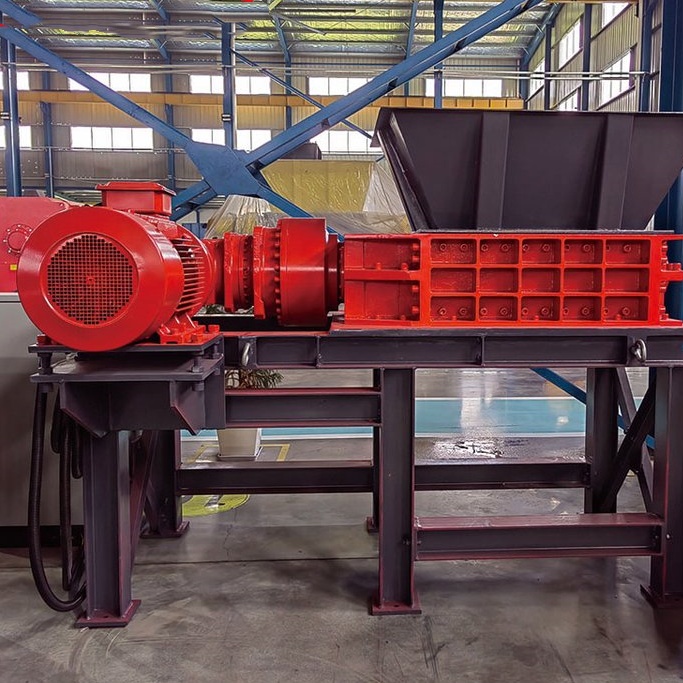

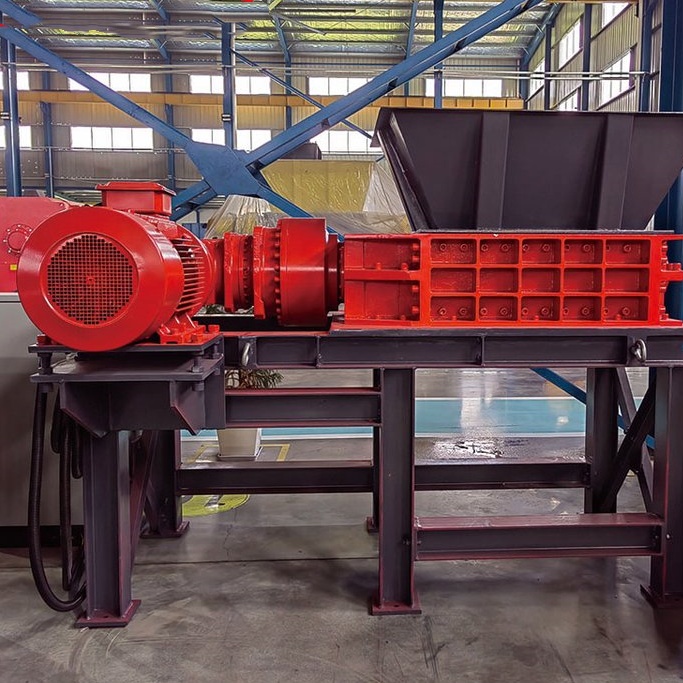

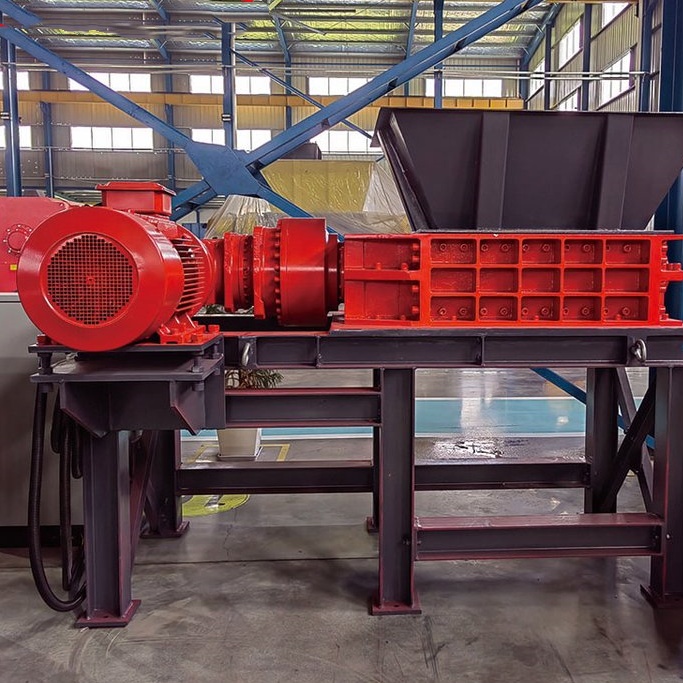

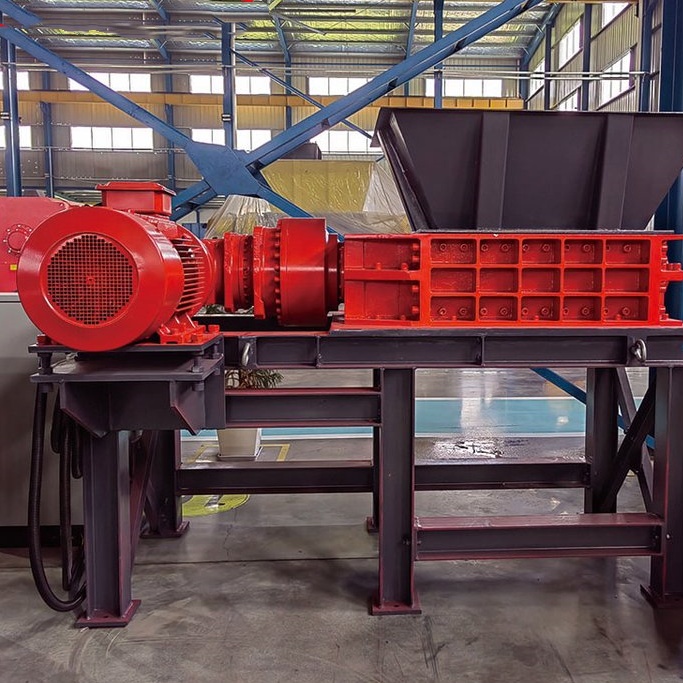

When we talk about the Waste Lead Acid Battery Crushing Breaking And Recovery Plant in a more specific way, we're referring to the scrap lead-acid battery crusher (crushing and separating machine). It's designed to deal with used/wasted lead-acid batteries and get back the lead, plastic, and other stuff. This machine crushes and separates the old batteries, making a mix of lead metals, lead paste, plastic, and other stuff. After that, the materials go through screening and classification before they get smelted or recycled before being sent for smelting and recycling.

Usually, the scrap lead-acid battery crusher has a feed inlet, a crushing chamber, a filtering device, and an outlet. The crushing chamber has crushing hammers, with the feed inlet above and the outlet below. The filtering device is strategically placed between the hammers and the outlet. The hammers include a rotating shaft, a hammer disc, and a hammer body. The shaft moves through the chamber, with the disc attached. The center of the disc lines up with the shaft's central axis, and the disc is at a right angle to the shaft. The hammer body is fixed on the shaft.

Spent Lead Acid Battery Recovery Equipment Basic information

Item | Index | Remark |

Equipment name | Spent Lead Acid Battery Recovery Equipment |

|

Raw materials | Spent Lead Acid Battery | Also known as wasted lead battery |

Output | Lead, lead plaster, plastic |

|

Final product | Refined lead and refined tin* | ≥99.9% Pb and ≥99.9%Sn ingot |

*Note: if the owner need to produce refined tin using the byproduct from lead smelting, the lead-tin vacuum distillation furnace has to be employed.

Relevant equipment:

Lead tin vacuum distillation furnace, lead tilting furnace, lead side blow furnace

Packing and delivering

Professional seaworthy or airway package and delivery will be provided.

FAQ

Q1: What payment terms are accepted?

A: LC and TT

Q2: How long is the lead time?

A: 180 days

Q3: Can you provide on-site service?

A: Yes we could provide full set service from design to installation and trail production.