scrap copper recycling plant

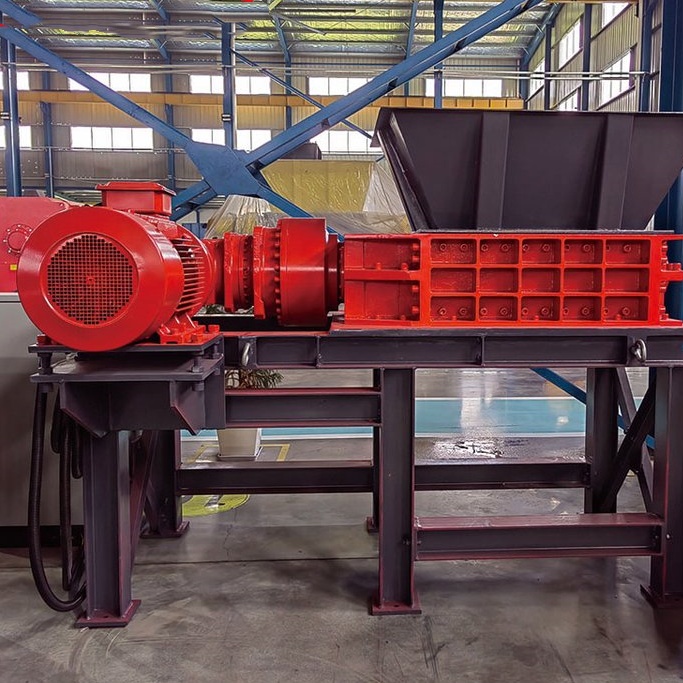

scrap copper recycling plant comprises of materials crushing and separating machine, scrap copper reducing and melting tilting furnace, crude copper anode ingot casting machine, AC-DC rectifier transformer, polymer concrete electrolytic cell, stainless steel cathode, copper busbar and other equipment.Our team can design and supply a complete scrap copper recycling plant.

Copper (Symbol Cu) is one of the valuable metals widely used around the world from electrical wiring to construction materials. Copper is among the most easily recycled metals thanks to its and stable property and versatility. Needless to say, scrap copper recycling is regarded as the most important metal production process to guarantee the sustainable development.

Scrap copper recycling process comprises of several key steps. First, the scrap copper is collected from various sources, such as electronic waste (e-waste), cables, or plumbing materials.

Once collected, the materials (such as waste (e-waste), cables, or plumbing materials) are crushed and separated using special-designed cable or e-waste crushing and separating machine to sort different metals such as iron (Fe), copper(Cu), tin(Sn), nickel(Ni) and other material such as plastic and rubber.

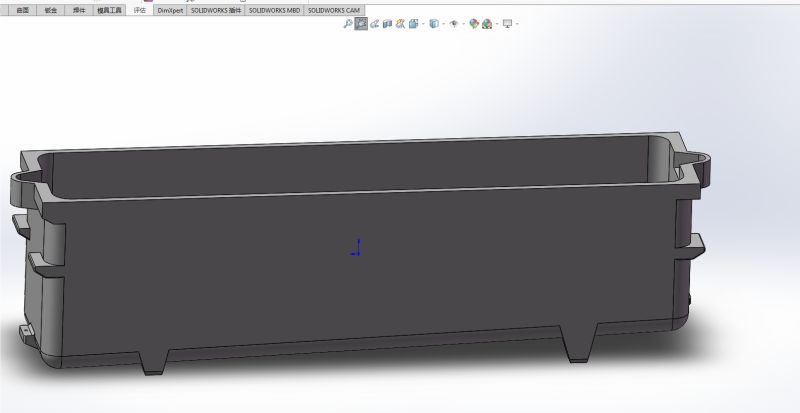

Next, the sorted scrap copper (Cu≥93%)is melted down in a tilting furnace to produce crude copper anode . Copper anode is an intermediate product that contains impurities like silver(Ag), gold(Au) and needs further refining.

At final stage, the copper anode undergoes the electrorefining process to remove impurities and produce refined copper (≥99.9% Cu).

The crude copper anodes and stainless steel cathode are put into the electrolytic cell. The DC currents pass through anodes and cathodes making copper ion migrate to the cathode and form copper layers (≥99.9% Cu) on the cathode surfaces.

During this process, the impurities remain in the cell as the anode slime containing precious metals like silver(Ag) and gold(Au).

Overall, the scrap copper recycling process involves collecting, sorting, melting, electrorefining, and producing refined copper, which can be reused in various applications.

Parameters table

Item | UOM | Index |

Raw material copper content | % | Cu ≥93% |

Crude copper anode copper content | % | Cu ≥93% |

Annually Copper scrap treating capacity | TPA | 1,000-100,000 |

Cu pyro-smelting direct recovery rate | % | 98.4% |

Crude anode copper content | % | Above 93% |

Crude Copper ingot annual production capacity | Tpa | 1,000-100,000 |

Refined copper content | % | ≥99.95% |